Polycarboxylate Superplasticizer Ether (PC-P)

Product Name: Polycarboxylate Superplasticizer (PC-P)

Type: PC-P(Powder)

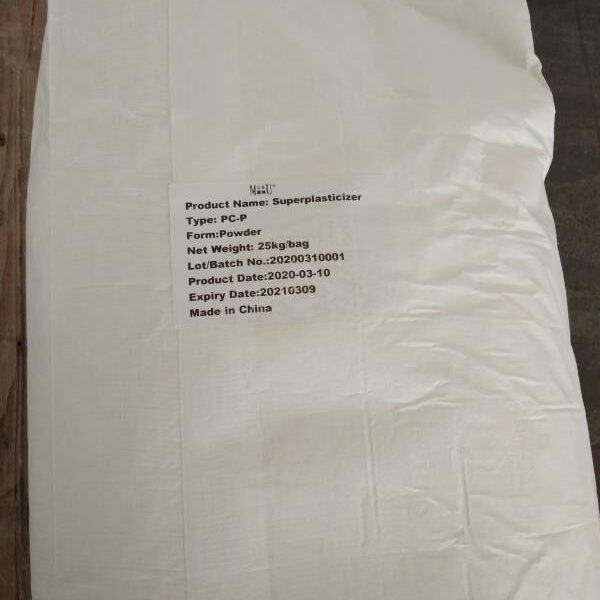

Package: 25 kg / bag

Polycarboxylate Superplasticizer (PC-P) is free-flowing and spray dried powder, affords excellent control over initial and final setting times.

Superplasticizer

PC-P

Description

Superplasticizer offered by MUHU USA is a powerful chemical admixture that improves concrete workability while allowing substantial water reduction. It is suitable for modern, high-performance concrete, enabling a more flowable mix with less water, resulting in a denser, stronger, and longer-lasting concrete.

The polycarboxylate superplasticizer ether or PC-P is a free-flowing and spray-dried powder of new-generation polycarboxylate-based polymer, which is used for cement-based materials. Used in applications ranging from self-leveling screeds, grouts, and repair mortars to floor screeds, coatings, and high-strength structural concretes. Our superplasticizer ensures superior plasticizing performance and uniform cement dispersion.

The result: easier mixing and placement, faster strength gain, reduced shrinkage and permeability, and concrete that stands up to demanding environments with better durability and performance.

Special Features

- High-efficient water reduction up to 30%

- Excellent stability, providing long working time

- Unique homogeneous plasticizing property, thus preventing segregation and bleeding

- Good disperser for various types of cement, gypsum, and minerals

Specifications

| Items | Specification |

|---|---|

| Visual Appearance | Light Yellow Powder |

| Bulk Density (kg/m³) | 510 ± 10 |

| Drying Loss (%) | 2.0 ± 1.0 |

| pH (23℃, 20% solution) | 9.0 ± 0.5 |

| Solid Content (%) | 98.0 ± 1.0 |

| Solubility | Water Soluble |

| Performance | Dosage for P.O 42.5 Standard Cement: 0.2 ± 0.02% |

| Cement Paste Flow: ≥240 | |

| Water Reducing of Mortar (%) | ≥20 |

Uses

- Self-leveling

- Structure grout

- Cable grout

- Repair mortar

- Floor screed / thin-overlay

- Cement coating / paint

- Gypsum, ceramic products

- Products with silica fume, silica flour, pigment, and other ultra-fine particles

- Architectural products

Typical Applications & Advantages

- Produces high-quality durable concrete

- Powerful plasticizing action with improved initial workability and faster strength development

- Maximizes water-cement ratio reduction for high-strength concrete

- Delivers high-performance concrete reliably to job sites

- Can be used alone or with other additives for special concretes like pumping and ready-mix

Technical Support

MUHU provides comprehensive technical support to specifiers, end users, and contractors, including on-site technical assistance.

Instructions for Use

Polycarboxylate Superplasticizer

should preferably be added to the mixing water. For ready-mix concrete, it can be added to fresh concrete in a mixing truck with high-speed mixing for 6–8 minutes.

Test Data Sheet

| Test Items | Actual Results | |

|---|---|---|

| Water Reduction (%) | 31 | |

| Air Content (%) | 5.2 | |

| Slump Retention (60 min) (mm) | 195 | |

| Compressive Strength Ratio (%) | 1 day | 198 |

| 3 day | 177 | |

| 7 day | 162 | |

| 28 day | 135 | |

| Bleeding Ratio (%) | 33 | |

| Shrinkage (28 day) (%) | 88 | |

| Setting Time Difference | Initial (min) | -90 ~ +120 |

| Final (min) | ||

Dosage

The recommended dosage of PC-P for various applications is 0.02% to 0.3% of the cementitious binder.

Setting

PC-P provides excellent control over initial and final setting times. These times depend on cement type, mix design, and ambient conditions.

Compatibility

Do not use PC-P with other admixtures unless approved by MUHU.

Packaging & Storage

PC-P is packed in 25 kg bags. Shelf life is 12 months if stored under cover and out of direct sunlight.

Health & Safety Precautions

PC-P is not classified as hazardous. However, avoid contact with skin or eyes and do not ingest. Use protective gloves and goggles. In case of contact, rinse with water. If swallowed, seek medical attention immediately and do not induce vomiting.

Refer to the Material Safety Data Sheet (MSDS) for more details.

Important Note

MUHU makes every effort to ensure this technical information is accurate. However, no warranty is expressed or implied. Suitability for specific applications is the user’s responsibility. Always confirm actual conditions align with MUHU’s recommendations.

Stainless Steel Polycarboxylate Superplasticizer Ether Synthetic Production Line

Be the first to review “Polycarboxylate Superplasticizer Ether (PC-P)” Cancel reply

You must be logged in to post a review.

frank@muhu-usa.com

frank@muhu-usa.com

(708) 966 6078

(708) 966 6078

Reviews

There are no reviews yet.