Laboratory Cement Mortar Mixer

(MH-MIXER-20I)

Uses and scope of application

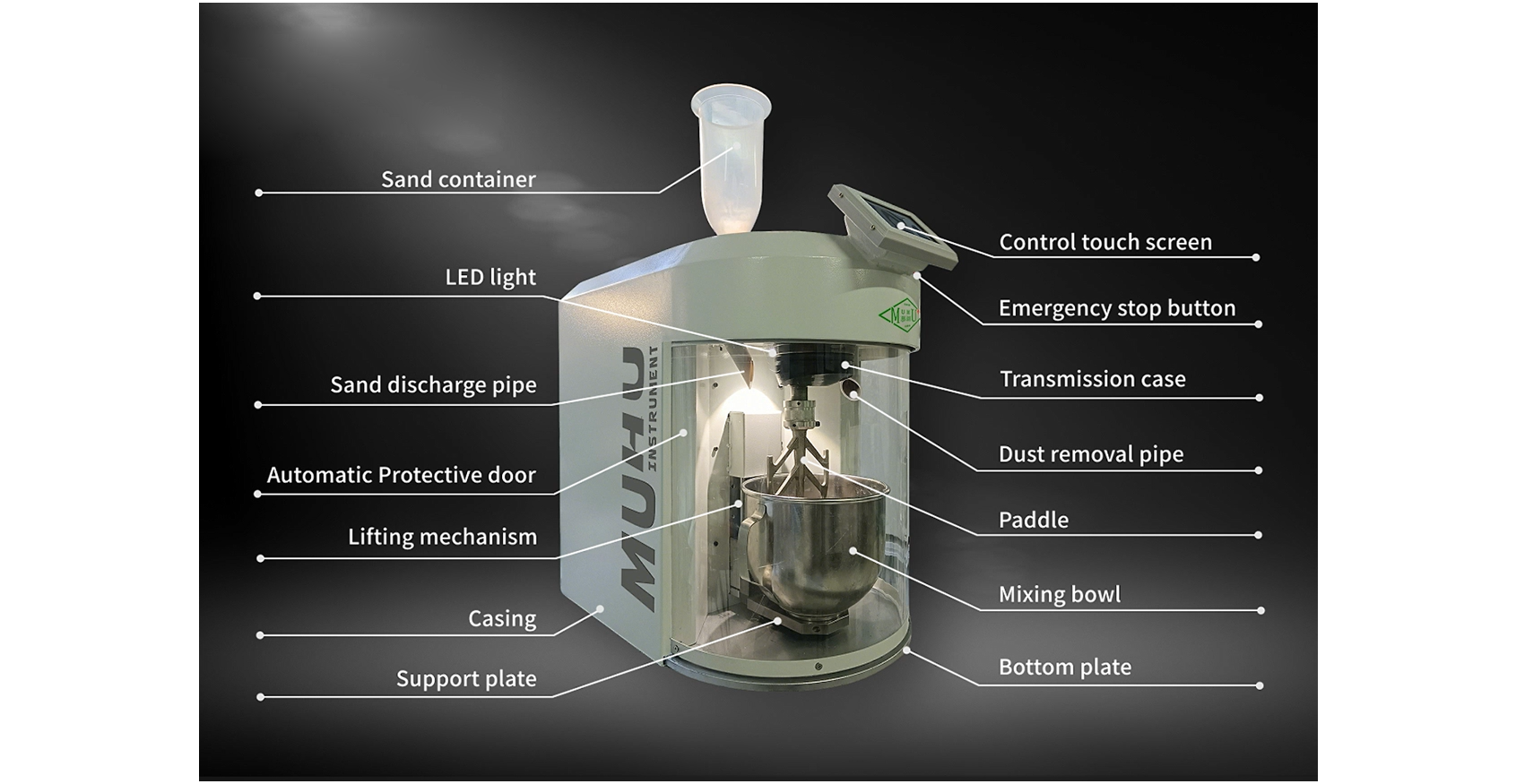

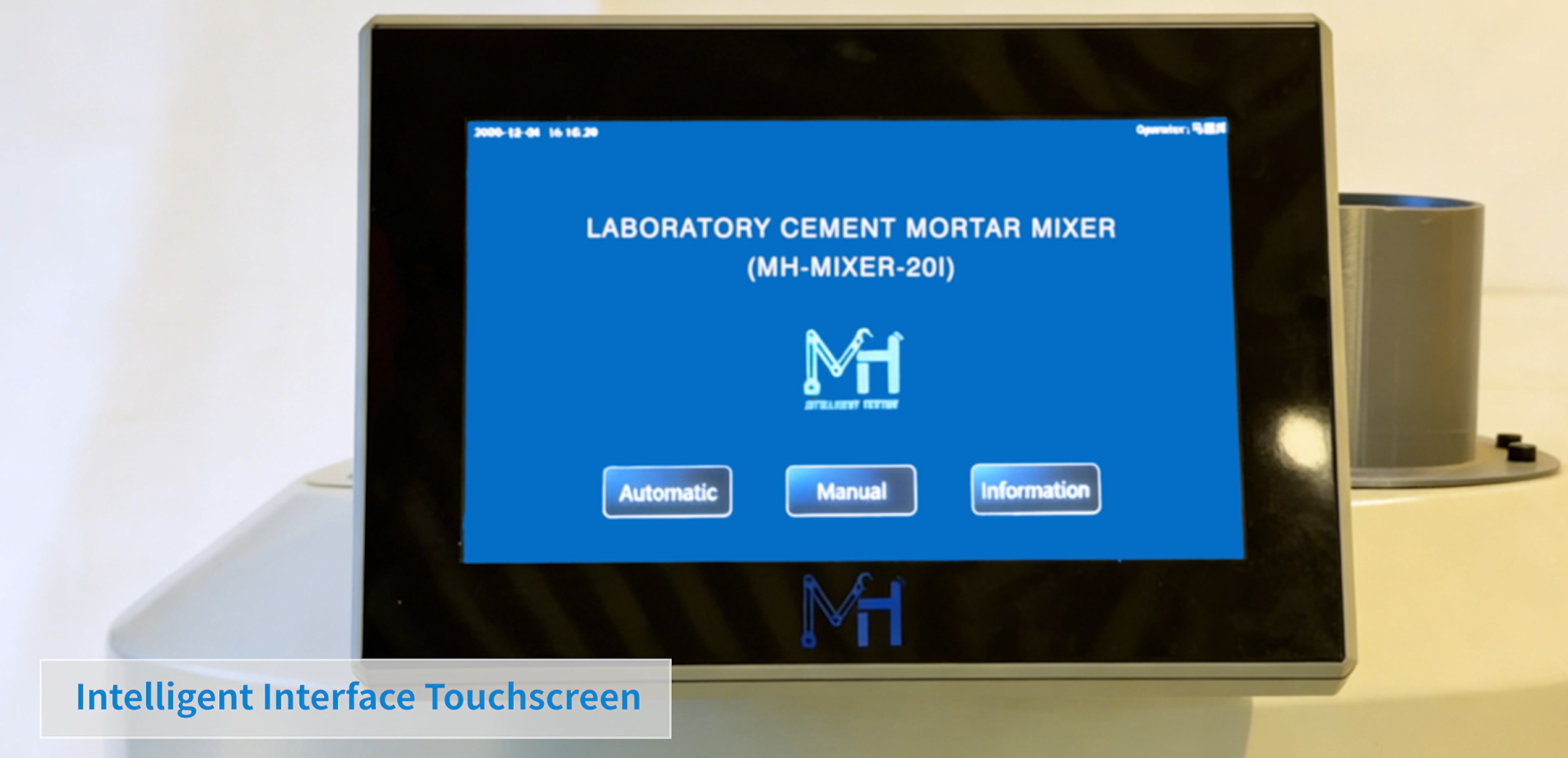

MH-MIXER-20I type Cement Mortar Mixer covering the following standards: ASTM C305, AASHTO T162, EN 196, DIN 1164, BS 3892, ISO 679, NF P15-411. Two-speed mixer designed to mix cement pastes and mortars.

This mixer is one of the most valuable and indispensable pieces of equipment for cement plants, building construction units, technical/professional colleges and scientific research units for cement laboratories.

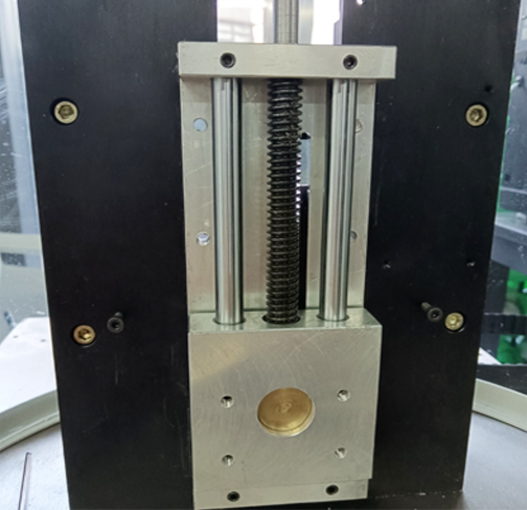

This cement laboratory equipment offers highest precision, ultra-low noise; protection against dust emissions, energy saving and environmental protection all featuring automatic lifting, and simple operation.

Product specifications and details

- 5 Liter stainless steel bowl and ASTM stirrer with a two-speed motor which runs at either 140 ±5 rpm or 285 ±10rpm.

- Electrical specification is: 110/220V 50/60Hz

- Total power of the whole machine:1000 W

- The motor is a single-phase AC servo motor, the power:750 W

- Equipment net weight:90 kg

- Package Size: 770mmⅹ520mmⅹ820mm

Mixer features

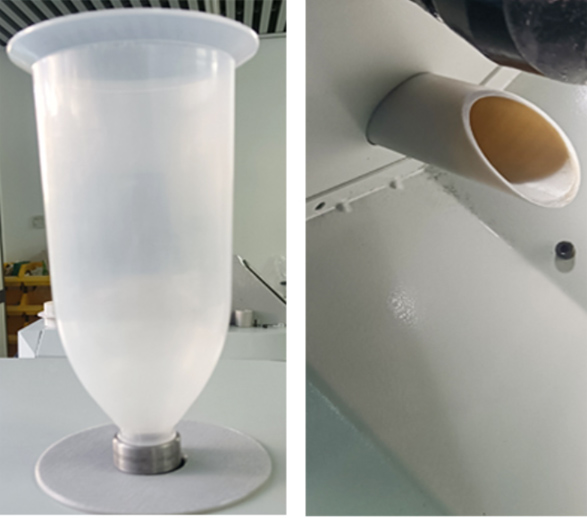

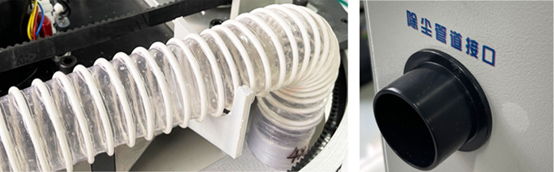

2. Dust removal system

Powerful, clean and environmentally friendly dust removal system

3. Illumination

LED lighting from top to bowl, allowing enhanced visibility during operation.

4. Emergency stop

In case of emergencies, operations can be terminated with one key that has multiple protection functions.

Procedure for Mixing Mortars

Place the dry paddle and the dry bowl in the mixing position in the mixer. Then introduce the materials for a batch into the bowl and mix in the following manner:

1.Place all the mixing water in the bowl.

2.Add the cement to the water; then start the mixer and mix at the slow speed (140±5 r/min) for 30 seconds.

3.Add the entire quantity of sand slowly over a 30 second period, while mixing at slow speed.

4.Stop the mixer, change to medium speed (285±10 r/min), and mix for 30 seconds

5.Stop the mixer and let the mortar stand for 90 s. During the first 15 seconds of this interval, quickly scrape down into the batch any mortar that may have collected on the side of the bowl; then for the remainder of this interval, close the mixer enclosure or cover the bowl with the lid.

6.Finish by mixing for 60 seconds at medium speed (285±10 r/min).

7.In any case requiring a remixing interval, any mortar adhering to the side of the bowl shall be quickly scraped down into the batch with the scraper prior to remixing.

Mixer design conforms to CE standards, featuring a mixing bowl screen, electronic position monitoring of the mixing bowl, emergency stop switch and restart protection.

Warning—The clearances between the paddle and the bowl specified in this practice are suitable when using mortar made with standard sand as described in Specification C 778. To permit the mixer to operate freely and to avoid serious damage to the paddle and bowl when coarser aggregates are used, it may be necessary to set the clearance adjustment bracket to provide greater clearances than those specified in 4.1.

frank@muhu-usa.com

frank@muhu-usa.com

(708) 966 6078

(708) 966 6078