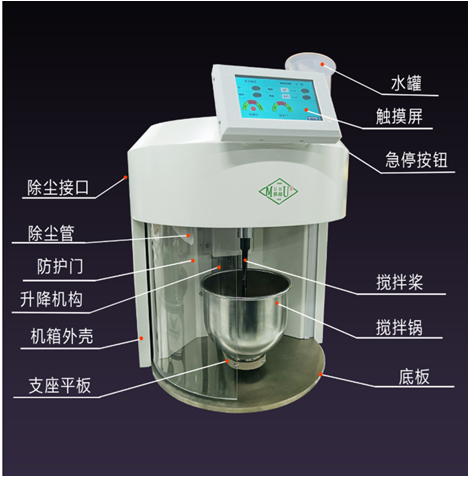

Laboratory Cement Paste Mixer

(MH-MIXER-16I)

Uses and scope of application

MH-MIXER-16I type Cement Paste Mixercovering the following standards: ASTM C305, EN 196 -1,3,9; EN 480 and EN 413.Two-speed mixer designed to mix cement pastes.

According to relevant standards, the cement and water are mixed and stirred into a uniform test slurry that is used for measuring the standard consistency of cement, setting time and making stability test blocks. It is ideal for cement plants, construction units, technical professional colleges and scientific research units. This cement laboratory equipment offers highest precision, ultra-low noise; protection against dust emissions, energy saving and environmental protection all featuring automatic lifting, and simple operation.

Product specifications and details

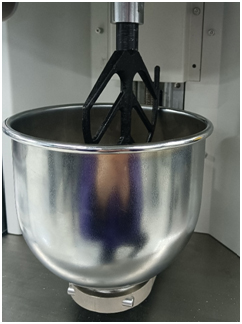

- 5 Liter stainless steel bowl and ASTM stirrer, and a two-speed motor, which runs at either 140 ±5 rpm or 285 ±10rpm.

- Electrical specification is: 110/220V 50/60Hz

- Total power of the whole machine:700 W

- The motor is a single-phase AC servo motor, the power:400 W

- Equipment net weight:66kg

- Package Size:770mmⅹ520mmⅹ820mm

Equipment composition

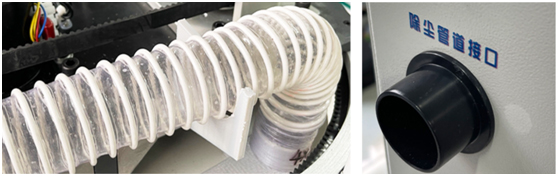

- Dust removal pipeline interface

- Dust removal pipe

- Automatic Protective door

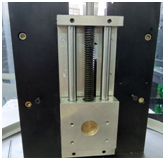

- Lifting mechanism

- Casing

- Support plate

- Water input port

- Control touch screen

- Emergency stop button

- Paddle

- Mixing Bowl

- Bottom plate

Mixer features

1. Intelligent interface touchscreen

The intelligent interface touch screen has precision touch, high stabilityand simple and convenient operation. The mixer has two modes, automatic and manual, which can be switched automatically according to requirements.

2. Dust removal system

Powerful, clean and environmentally friendly dust removal system

3. Illumination

LED lighting from top to bowl, allowing enhanced visibility during operation.

4. Emergency stop

In case of emergencies, operations can be terminated with one key that has multiple protection functions.

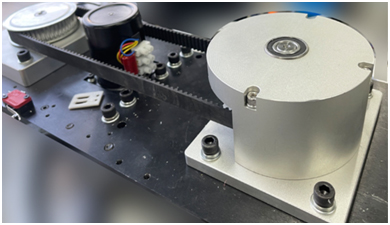

9. Servo motor transmission:

The main spindle uses a servo motor soft drive system resulting in low noise, stable operation, and high accuracy.

Procedure for Mixing Pastes

- 1. Place the dry paddle and the dry bowl in the mixing position in the mixer. Then introduce the materials for a batch into the bowl and mix in the following manner:

- 2. Placeallthemixingwaterinthebowl.

- 3. Add the cement to the water and allow 30 s for the absorption of the water.

- 4. Start the mixer and mix at slow speed (140 6 5 r/min) for 30 s.

- 5. Stop the mixer for 15 s and during this time scrape downintothebatchanypastethatmayhavecollectedonsides of the bowl.

- 6. Start the mixer at medium speed (285 610 r/min) and mix for 60 s.

Mixer design conforms to CE standards, featuring a mixing bowl screen, electronic position monitoring of the mixing bowl, emergency stop switch and restart protection.

frank@muhu-usa.com

frank@muhu-usa.com

(708) 966 6078

(708) 966 6078