Polycarboxylate Superplasticizer

Product Name: Polycarboxylate Ether Superplasticizer

Type: PC-P / PC-F / PC-E / P-R / PC-808 /PC-608 /PC-708

Package: 25kg/bag, 1100 kg / IBC Tank ,230kg/drum

Polycarboxylate Superplasticizer is an advanced admixture allows the reduction of the water to cement ratio without affecting the workability of the mixture. It also enables the production of high strength and high-performance concrete.

Learn more Polycarboxylate Superplasticizer Synthesis Equipment, click this link.

Key words:

1. polycarboxylate superplasticizer

2. Polycarboxylate concrete admixture

3. polycarboxylate ether

4. polycarboxylate ether superplasticizer

5. Superplasticizer

Polycarboxylate Ether

Description

Polycarboxylate Ether is a next-generation polymer superplasticizer designed for cement, gypsum, ceramic mixtures, and other mineral-based materials. It is ideal for high-performance and high-strength concrete, as well as mixes containing large amounts of fly ash, slag, or those used for grouting and self-leveling applications.

PC-P meets ASTM C 494 Type-F requirements and delivers powerful water reduction, excellent stability, and uniform plasticizing action. It is commonly used in self-leveling compounds, structural and cable grouts, repair mortars, floor screeds, cement coatings, and architectural products. This additive enhances durability, improves mix quality, optimizes the water-cement ratio, and can be used alone or combined with other admixtures.

Standard Compliance

Polycarboxylate Superplasticizer complies with the requirements of the following standards: ASTM C 494, Type F,G and E. BS EN 934-2.

Typical Properties

| Items | Specification | ||||||

|---|---|---|---|---|---|---|---|

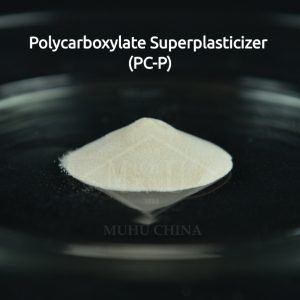

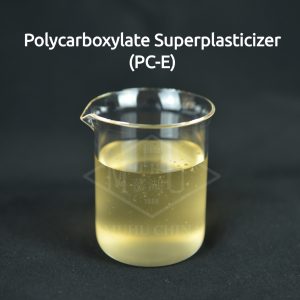

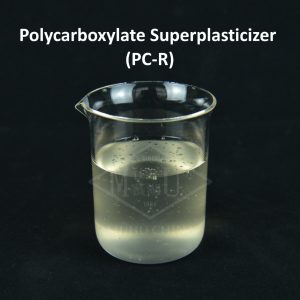

| PC-P (Powder) | PC-F (50%) (High Water Reduce Rate) | PC-E (52%) (Ultra Early Strength) | PC-R (50%) (Super Set Retarder) | PC-808 Flake (High Water Reduction) | PC-708 Flake (High Slump Retention) | PC-608 Flake (Special Set Retarder) | |

| Visual Appearance | Light Yellow Powder | Light Yellow Liquid | Light Yellow Liquid | Light Yellow Liquid | White Solid Flake | ||

| Solid Content (%) | 98.0±1.0 | 50.0±2.0 | 50.0±2.0 | 50.0±2.0 | 96% | ||

| Density (23℃)(kg/m³) | 600±30 | ≥1.05 | ≥1.05 | ≥1.05 | — | ||

| Chloride Content (%) | ≤0 | ≤0 | ≤0 | ≤0 | ≤0 | ||

| Solubility | Completely Soluble | Completely Soluble | Completely Soluble | Completely Soluble | Completely Soluble | ||

Uses of Polycarboxylate concrete admixture:

- To obtain a high-quality concrete mix with accelerated strength development and extended workability without delayed setting characteristics.

- To provide a concrete mix with exceptional placing characteristics and accelerated cement hydration for early strength development and high-quality concrete.

- To provide improved durability by increasing ultimate strengths and reducing concrete permeability.

Typical Applications & Advantages:

- Provides high-quality durable concrete.

- Powerful plasticizing action with an improved initial workability, easier placing and faster strength development.

- Reduces water/cement ratio to the maximum that allows for the production of high strength concrete.

- Capability of delivering high performance concrete at any time to a job site.

- Polycarboxylate Concrete Admixture can be used alone or with other additives for special concrete such as pumping concrete, ready mixed concrete etc.

Technical Support and Services:

MUHU offers one-stop type services and turn-key projects.

Our system adopts heatless production instead of using traditional heating sources, greatly reducing costs for equipment and energy. It improves production formula and equipment to enable localized production, with no waste discharge. Features include: energy saving, automation, precise controls, low investment, convenient feeding, fast production, easy maintenance, and high efficiency.

Instructions for Use

Add Polycarboxylate Superplasticizer preferably to mixing water. In ready mixed concrete, it can be added to fresh concrete in a mixing truck. Mix at high speed for 6–8 minutes.

Dosage

Determine the optimal dosage of Polycarboxylate Superplasticizer by trials using site materials and conditions.

Setting

Provides excellent control over initial and final setting times. Settings depend on cement type, mix design, and ambient temperature.

Compatibility

Do not use with other admixtures without prior approval from MUHU.

Packaging & Storage

- PC-P: 25kg/bag.

- PC-F/R/E: 1100kg IBC tank, 230kg drum or flex tank. Bulk site delivery available.

- Shelf life: 12 months under cover and out of direct sunlight.

Health & Safety Precautions

Polycarboxylate Ether Superplasticizer is not classified as hazardous, but avoid ingestion and contact with skin/eyes. Use gloves and goggles. Rinse eyes with water and seek medical attention if needed. If swallowed, do not induce vomiting—seek medical help.

Important note

MUHU provides technical information to the best of its knowledge. No warranty is implied. Ensure suitability of the product for intended application.

Be the first to review “Polycarboxylate Superplasticizer” Cancel reply

You must be logged in to post a review.

frank@muhu-usa.com

frank@muhu-usa.com

(708) 966 6078

(708) 966 6078

Reviews

There are no reviews yet.