Keywords: polycarboxylate ether production, Polycarboxylate Superplasticizer Synthesis Equipment, Plant Large Scale production Equipment, Large Scale equipment, buy Large Scale production system, Plant Large Scale production system, produce polycarboxylate Ether superplasticizer, plant admixture production systems, concrete admixtures plant, produce Polycarboxylate Superplasticizer, produce concrete admixtures, Ultra high performance concrete additives Equipment, Large Scale production, Lab Scale Production System of Polycarboxylate Superplasticizer, plant admixture Large Scale production systems, produce polycarboxylate superplasticizer for concrete, produce polycarboxylate superplasticizer for concrete admixture.

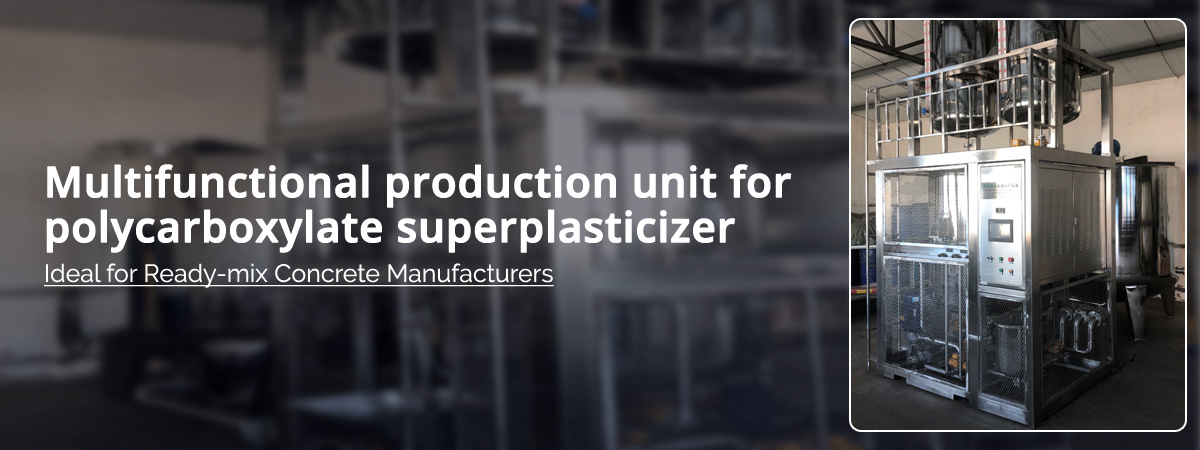

Multifunctional Production Unit for Polycarboxylate Superplasticizer

Stainless Steel Type

MH-PCS-02AS (5T)

Ideal for Ready-mix Concrete Manufacturers

■ Overview

After continuous improvements and innovations to the previous equipment, MUHU engineers developed this mobile and integrated production unit. This new system is featuring a unique design with Stainless Steel and Modular-based Remote Control which is the break-through in the industry in China. It offers environmental protection with zero waste emissions or discharges.

This type is designed for concrete admixture plants. The machine can be used to produce high water reducing type PC-F (polycarboxylate superplasticizer) polymers and high-slump retention type PC-R (polycarboxylate superplasticizer retarder) polymers at ambient temperatures. In addition, this equipment can also be used for blending/batching polycarboxylate based retarding admixtures used in RMC plants. The whole production process is automatically controlled to ensure the stability of the products’ quality.

Watch this video ( https://youtu.be/1aZmZWx3wUE ) for detailed information of large-scale production systems for PCE Superplasticizers in Stainless steel.

■ Typical Properties

This equipment has the following unique features:

- Unique design with stainless steel: Special material feeding design for large quantity of powder products making it easy and fast to load TPEG/HPEG monomer material.

- Eliminating the traditional platform: Ground-floor material feeding operations decrease the requirement to the production setting (5 meter for workshop height) and increase safety.

- Removable and modular based: The installation and disassembly are fast and easy which makes it convenient to produce in different locations. Thus, it greatly reduces the cost of shipping materials to different locations.

- Automatic control and smart production: The system is designed for on-button control, intelligent production with all feedback signal automatic control, and entire process monitoring. The system can automatically adjust mixing time and materials adding speed based on the chemical reaction temperature in the production. Therefore, the product quality is assured.

- Automatic temperature compensation: In order to make the monomer easy to dissolve and have stable chemical reaction in winter season or in low ambient temperature. MUHU engineers designed this temperature compensation feature.

- Short process and high-efficiency: After the polymerization route for chemical reaction is optimized, the reaction time is shortened to 2 hours. The efficiency is 6 times that of tradition process. It only takes 3-4 hours to produce 5 tons of polycarboxylate superplasticizer polymers.

- Fully enclosed, non-polluting production: The enclosed production system is designed for zero emission of waste-water, gas and residue.

■ Snapshots of Production Line

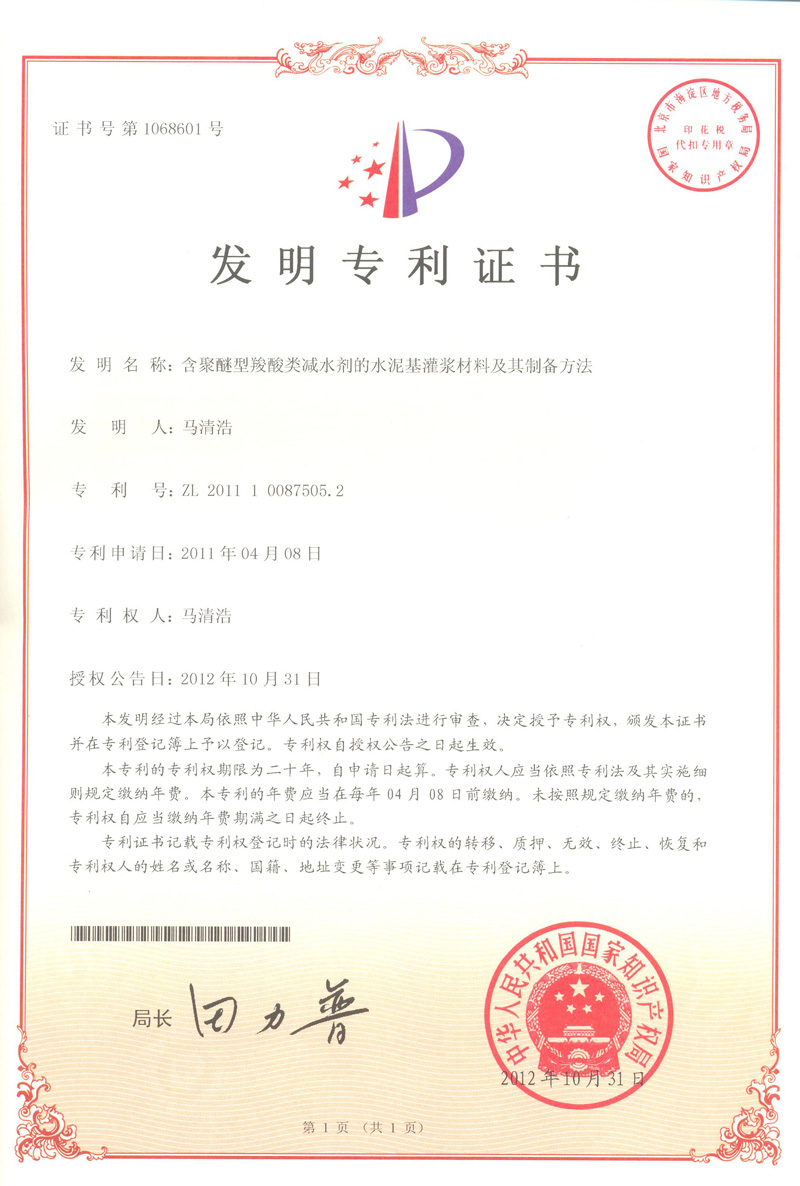

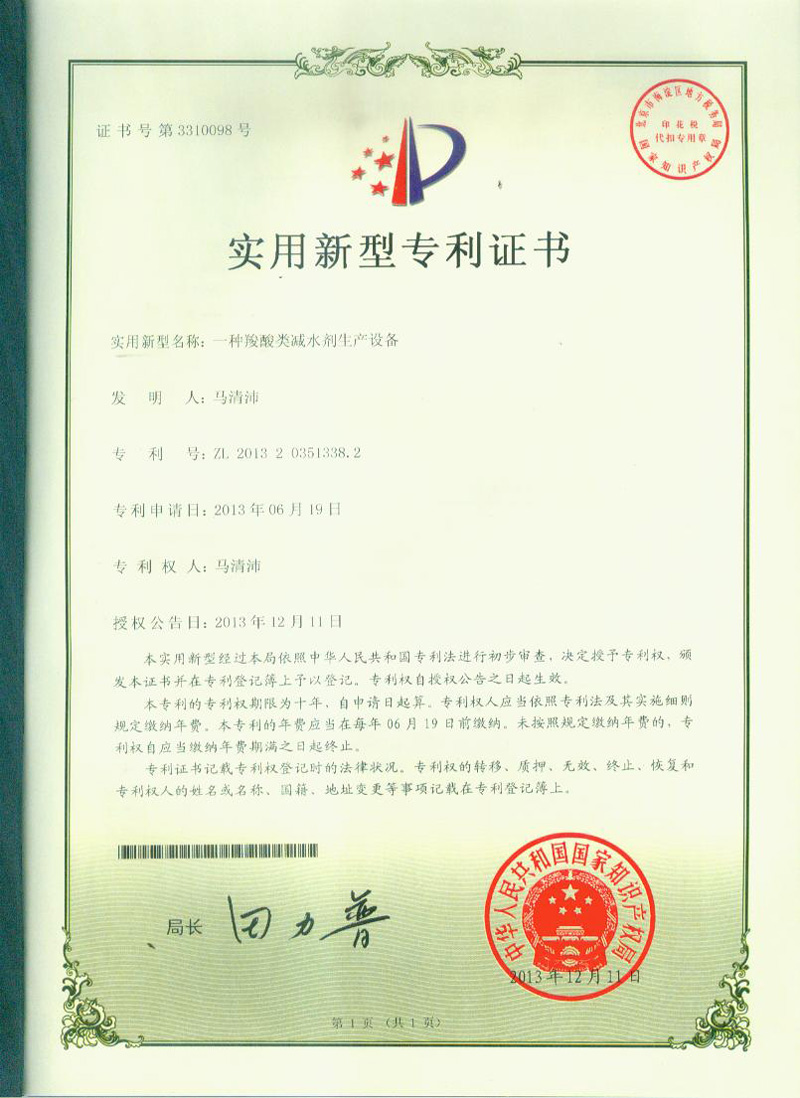

■ Patent certificates

In 2013, MUHU was granted the invention patent certificate for “polyether polycarboxylate superplasticizer formulation methods” and the applied patent certificate of “polyether production equipment”.

In 2003, MUHU polycarboxylate-type high performance water reducer was granted “new high tech products” by Beijing Government.

■ Plant requirements

- Building: ceiling height 24 ft; equipment floor is 5,000 sq ft

- Required power: 3-phase, 480 voltage,100 amps

- Water consumption: 5 to 30 tons/day

■ Technical Support Services

- We can show you how to use this equipment and produce polycarboxylate superplasticizer Ether.

- Our staff will provide guidance for installation, commissioning and production.

- Free staff training.

- PC based superplasticizer formula admixtures are free.

■ Capacity

One batch, 5 tons or 10 tons, needs 6-7 hours for production.

■ Partnerships

We can provide our partners with the equipment they need.

MUHU will always be customer-centric and continuously focused on being your reliable partner in the admixture industry.

■ Production raw material

In addition to product formulas and production equipment, MUHU also provides raw materials for production based on customers’ specific requirements. Using MUHU products and raw materials has the following advantages:

1. MUHU has been working together with major raw material suppliers in China for a long-term. Bulk procurement can assure highest quality at lower costs.

2. MUHU has stringent inspection technology and quality assurance systems that ensure the quality of each batch of raw material meets or exceeds every production requirement. Thus, MUHU’s partners may save on inspection processes and costs.

3. MUHU owns warehouses with over 10,000 SQ meters. Product inventory is high and variety is wide. Our inventories ensure stable supplies in demanding supply markets.

4. MUHU’s logistic teams can safely deliver raw materials to the customers on time and at reduced costs. Based on product formulas, customers may place orders at any time. MUHU provides one-stop shopping to help customers improve their cash flow.

■ Contact information

Frank White

MUHU (USA) Construction Materials

Florida, USA

Mobile: 708-966-6078

Email: frank@muhu-usa.com

frank@muhu-usa.com

frank@muhu-usa.com

(708) 966 6078

(708) 966 6078